News新闻资讯

Company news

home > news > Company news

Special Material——Carbon fibers

Tail of an RC helicopter, made of Carbon fiber reinforced polymer

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about 5–10 micrometres in diameter and composed mostly of carbon atoms.

To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the long axis of the fiber as the crystal alignment gives the fiber high strength-to-volume ratio (making it strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric.

The properties of carbon fibers, such as high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal expansion, make them very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports. However, they are relatively expensive when compared with similar fibers, such as glass fibers or plastic fibers.

Carbon fibers are usually combined with other materials to form a composite. When combined with a plastic resin and wound or molded it forms carbon-fiber-reinforced polymer (often referred to as carbon fiber) which has a very high strength-to-weight ratio, and is extremely rigid although somewhat brittle. However, carbon fibers are also composited with other materials, such as graphite, to form carbon-carbon composites, which have a very high heat tolerance.

1、Structure and properties

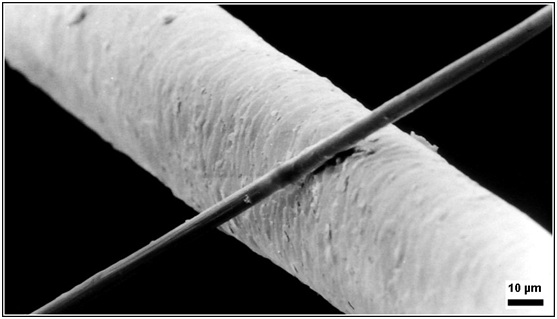

Carbon fiber is frequently supplied in the form of a continuous tow wound onto a reel. The tow is a bundle of thousands of continuous individual carbon filaments held together and protected by an organic coating, or size, such as polyethylene oxide (PEO) or polyvinyl alcohol (PVA). The tow can be conveniently unwound from the reel for use. Each carbon filament in the tow is a continuous cylinder with a diameter of 5–10 micrometers and consists almost exclusively of carbon. The earliest generation (e.g. T300, HTA and AS4) had diameters of 16–22 micrometers. Later fibers (e.g. IM6 or IM600) have diameters that are approximately 5 micrometers.

The atomic structure of carbon fiber is similar to that of graphite, consisting of sheets of carbon atoms arranged in a regular hexagonal pattern (graphene sheets), the difference being in the way these sheets interlock. Graphite is a crystalline material in which the sheets are stacked parallel to one another in regular fashion. The intermolecular forces between the sheets are relatively weak Van der Waals forces, giving graphite its soft and brittle characteristics.

Depending upon the precursor to make the fiber, carbon fiber may be turbostratic or graphitic, or have a hybrid structure with both graphitic and turbostratic parts present. In turbostratic carbon fiber the sheets of carbon atoms are haphazardly folded, or crumpled, together. Carbon fibers derived from polyacrylonitrile (PAN) are turbostratic, whereas carbon fibers derived from mesophase pitch are graphitic after heat treatment at temperatures exceeding 2200 °C. Turbostratic carbon fibers tend to have high tensile strength, whereas heat-treated mesophase-pitch-derived carbon fibers have high Young's modulus (i.e., high stiffness or resistance to extension under load) and high thermal conductivity.

A 6μm diameter carbon filament (running from bottom left to top right) compared to a human hair.

2)Textiles

Precursors for carbon fibers are polyacrylonitrile (PAN), rayon and pitch. Carbon fiber filament yarns are used in several processing techniques: the direct uses are for prepregging, filament winding, pultrusion, weaving, braiding, etc. Carbon fiber yarn is rated by the linear density (weight per unit length, i.e. 1 g/1000 m = 1 tex) or by number of filaments per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon fiber is three times as strong as 1,000 carbon filament yarn, but is also three times as heavy. This thread can then be used to weave a carbon fiber filament fabric or cloth. The appearance of this fabric generally depends on the linear density of the yarn and the weave chosen. Some commonly used types of weave are twill, satin and plain. Carbon filament yarns can also be knitted or braided.

2)Textiles

Precursors for carbon fibers are polyacrylonitrile (PAN), rayon and pitch. Carbon fiber filament yarns are used in several processing techniques: the direct uses are for prepregging, filament winding, pultrusion, weaving, braiding, etc. Carbon fiber yarn is rated by the linear density (weight per unit length, i.e. 1 g/1000 m = 1 tex) or by number of filaments per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon fiber is three times as strong as 1,000 carbon filament yarn, but is also three times as heavy. This thread can then be used to weave a carbon fiber filament fabric or cloth. The appearance of this fabric generally depends on the linear density of the yarn and the weave chosen. Some commonly used types of weave are twill, satin and plain. Carbon filament yarns can also be knitted or braided.

2、Applications

The global demand on carbon fiber composites was valued at roughly US$10.8 billion in 2009, which declined 8–10% from the previous year. It is expected to reach US$13.2 billion by 2012 and to increase to US$18.6 billion by 2015 with an annual growth rate of 7% or more. Strongest demands come from aircraft & aerospace, wind energy, as well as from the automotive industry with optimized resin systems.

1)Composite materials

Carbon fiber is most notably used to reinforce composite materials, particularly the class of materials known as carbon fiber or graphite reinforced polymers. Non-polymer materials can also be used as the matrix for carbon fibers. Due to the formation of metal carbides and corrosion considerations, carbon has seen limited success in metal matrix composite applications. Reinforced carbon-carbon (RCC) consists of carbon fiber-reinforced graphite, and is used structurally in high-temperature applications. The fiber also finds use in filtration of high-temperature gases, as an electrode with high surface area and impeccable corrosion resistance, and as an anti-static component. Molding a thin layer of carbon fibers significantly improves fire resistance of polymers or thermoset composites because a dense, compact layer of carbon fibers efficiently reflects heat.

The increasing use of carbon fiber composites is displacing aluminum from aerospace applications in favor of other metals because of galvanic corrosion issues

2)Textiles

Precursors for carbon fibers are polyacrylonitrile (PAN), rayon and pitch. Carbon fiber filament yarns are used in several processing techniques: the direct uses are for prepregging, filament winding, pultrusion, weaving, braiding, etc. Carbon fiber yarn is rated by the linear density (weight per unit length, i.e. 1 g/1000 m = 1 tex) or by number of filaments per yarn count, in thousands. For example, 200 tex for 3,000 filaments of carbon fiber is three times as strong as 1,000 carbon filament yarn, but is also three times as heavy. This thread can then be used to weave a carbon fiber filament fabric or cloth. The appearance of this fabric generally depends on the linear density of the yarn and the weave chosen. Some commonly used types of weave are twill, satin and plain. Carbon filament yarns can also be knitted or braided.

Motorcycle racing gloves with carbon fiber protectors for ligaments in fingers

3)Microelectrodes

Carbon fibers are used for fabrication of carbon-fiber microelectrodes. In this application typically a single carbon fiber with diameter of 5–7 μm is sealed in a glass capillary.[12] At the tip the capillary is either sealed with epoxy and polished to make carbon-fiber disk microelectrode or the fiber is cut to a length of 75–150 μm to make carbon-fiber cylinder electrode. Carbon-fiber microelectrodes are used either in amperometry or fast-scan cyclic voltammetry for detection of biochemical signaling.

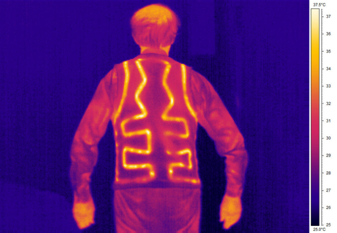

4)Flexible heating

Known for its conductivity, carbon fibers can carry very low currents on their own. When woven into larger fabrics, they can be used to reliably deliver infrared heating in applications requiring flexible heating elements and can easily sustain temperatures past 100 °C due to their physical properties. Many examples of this type of application can be seen in 'DIY' or Do it Yourself heated articles of clothing and blankets. Due to its chemical inertness, it can be used relatively safely amongst most fabrics and materials; however, shorts caused by the material folding back on itself will lead to increased heat production and can lead to fire.

A DIY carbon fiber heated jacket

At Henry, we have this special material Carbon fibers and production it by CNC machining,using in aerospace, civil engineering, military, and motorsports, along with other competition sports. Email Free Quote: sales@henryprototype.com to start your project review today.

- Home

- |

- About us

- |

- Product

- |

- News

- |

- Contact us

Email: info@henryproto.com

freequote@henryproto.com

Copyright:Hongkong Henry Prototype Co.,Ltd

Design by heyou51.com

China

China English

English